A Lempor Ejector for the Romulus

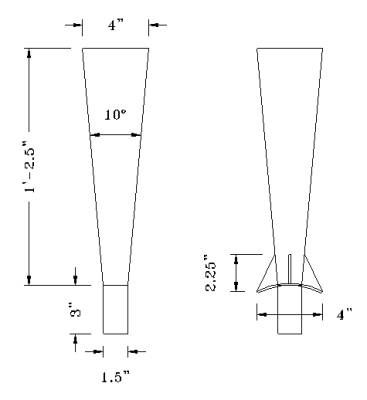

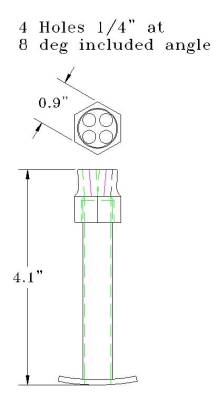

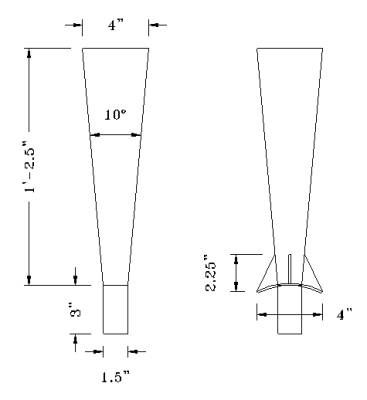

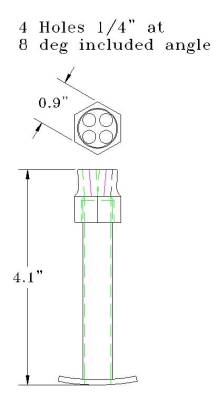

After the vacuum test I went ahead and designed a Lempor ejector for Lesley to see what actual difference it would make to performance. The old stack was a plain stovepipe 2-7/8" inside diameter built according to the drawings. The new diffuser will look like this. The diameters shown are inside. The calculation results gave four blast nozzles of 1/4" diameter. The fitting on the side of the blast pipe is for a back-pressure manometer connection. Where a photo has a blue border you can click for a larger picture.

Here are three photos of a quickie "built for test purposes" diffuser and mixing chamber for Romulus Lesley with the old straight stack for comparison.

The old stack, the new diffuser and looking through the diffuser at the 4-hole blast cap

Note the difference in throat diameters.

The First Lempor Ejector-Fitted Locomotive in Canada? Photos taken November 08 2005.

Click on the thumbnails for a larger photo.

The diffuser, newly fitted.

The new 4 hole blast nozzle in place.

The new 4 hole blast nozzle in place.

A Track Test

Me, my clipboard and a two-tube water manometer.

Inside the smokebox after the run.

Inside the smokebox after the run.

The purpose of this test was to quantify the maximum vacuum it was possible to attain with the new ejector and two test blast nozzles. Both the choke and blast nozzle hole dimensions were calculated using the "Lempor Ejector Calculator" spreadsheet.

Results were very positive and encouraging. The four-hole nozzle did less well than the single hole one but the diffuser and mixing chamber were a phenomenal improvement, reaching 5 inches of water vacuum (127mm) over the old stack's maximum of 2-1/4" (57mm) with the single 3/8" blast nozzle fitted. The four hole nozzle only reached 51mm water well below the target of 75mm but since it's area was 75% larger than the original nozzle, cylinder backpressure would be significantly lower resulting in higher engine power output.

Backpressure measurements were attempted but abandoned as the pressure in the blast pipe below both nozzles was higher than I could measure with the manometer I had. All I can say is that the back pressure below the four-hole nozzle was the lower of the two and was above 7 inches of water.

My conclusions are that the calculator spreadsheet works, the experiment was successful and tuning will show further improvement.

In Porta's introduction to his theory he says that proper tuning up "with measurements" is a requirement. My intent, therefore, is to make and try out several variations of the four-hole nozzle with different hole diameters and see what can be achieved on the track. Since I live in Canada and winter is now almost upon us this work will have to wait for the spring.