Krell KSA-100 Mk II restoration

Some photos of the process

This is an example of a fan cooled amp being disassembled

and cleaned. The amp is in otherwise perfect condition as it just sat there being

listened to for many years. There are several generations of these amps and I

have serviced all of them over the time I worked as a technician for the

distributor of Krell products in

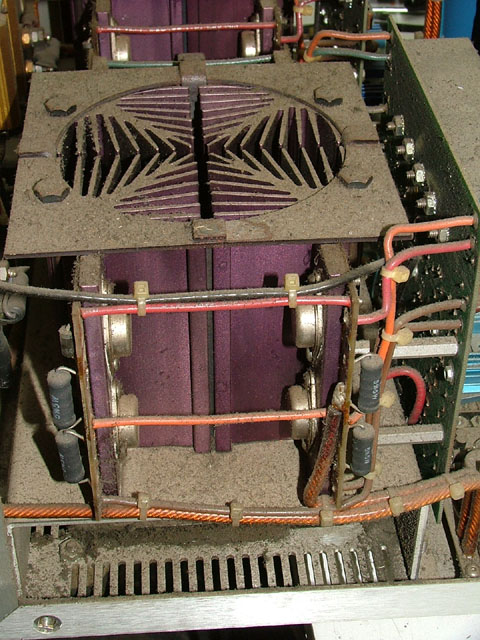

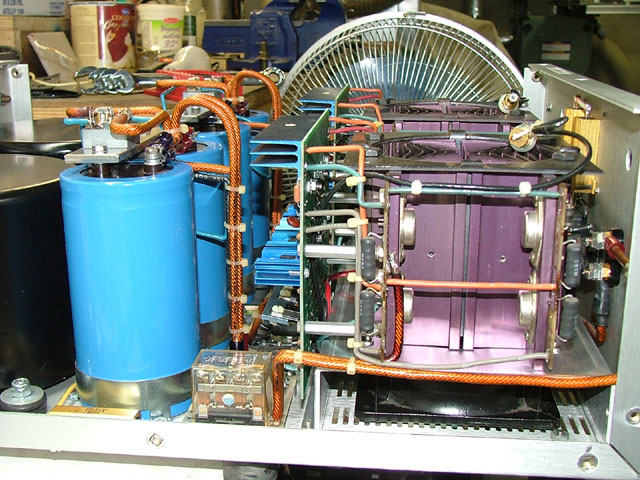

The insides; very dirty after years of use. The fans only make it worse.

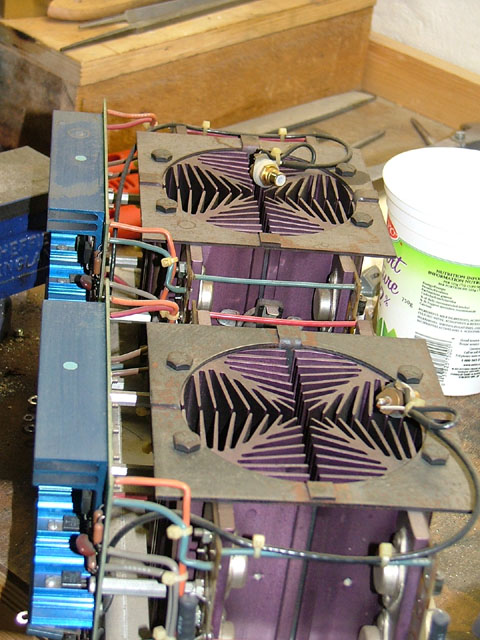

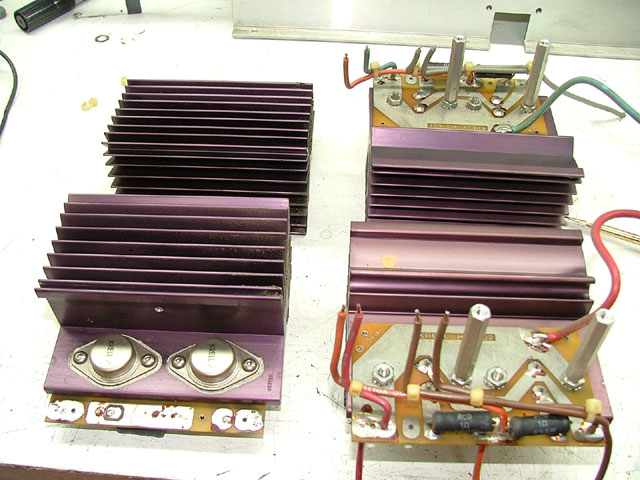

Side view of the heatsink/output assemblies. Dirt, dirt, dirt...

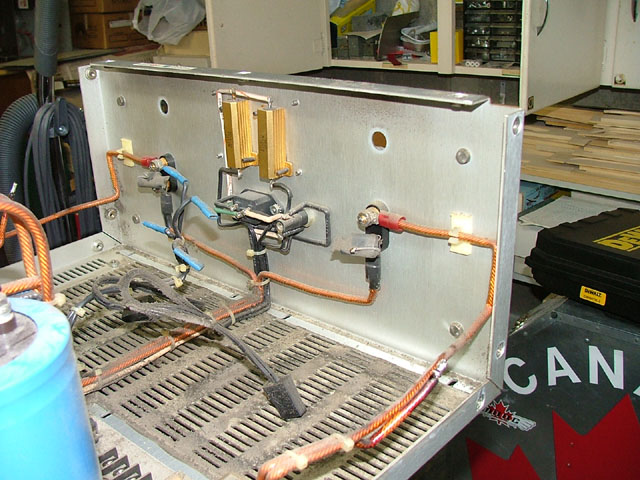

The cover, face plate and amplification module have been removed. The amplification module contains the main board, output stage and fans.

View of the inside rear of the amp showing the series resistors for the fans.

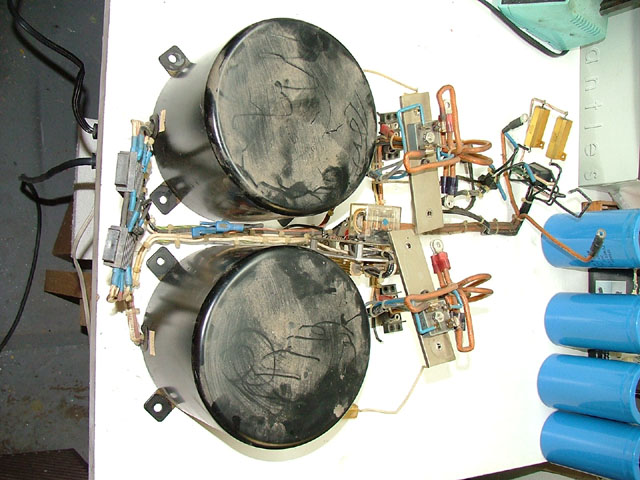

The transformers/harness have been removed and all that is left are the main cap clamps.

The main harness (including the transformers) was assembled at the factory in a jig outside the amp. It is removed as a unit.

Under the right channel transformer, the serial number of the unit was engraved at the factory.

The chassis has been cleaned and is ready to have the transformers and the rest of the main harness installed.

The transformers/harness has been cleaned and installed.

The face plate back in place.

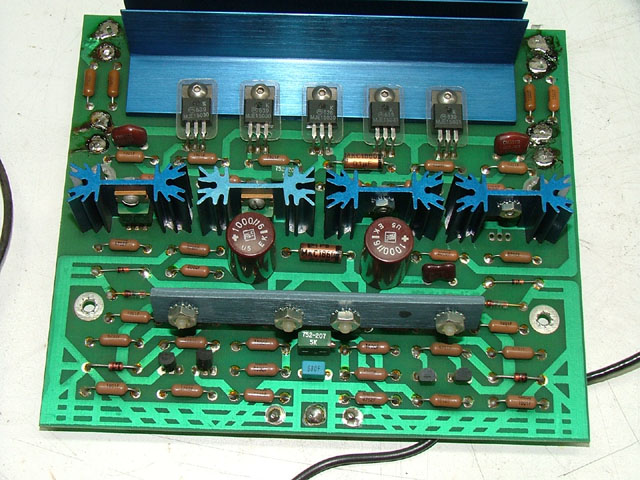

A view of the amplifier modules before disassembly and cleaning.

The main board has been cleaned. It includes everything up to the output stage.

The output stage has been disassembled from its bracket. The condition of the silicone heatsink compound must be assesed and replaced if necessary.

The cleaned amplification module ready for installation.

Almost done...

The amp is fully assembled now and is almost ready for adjustment and testing. Both the offset and bias are checked/adjusted on each channel and the output is checked for noise.

While the amps are very well made, there were inherent issues with the older fan cooled models. The fans were occasionally a source of trouble especially as they got dirty and the lubrication in the bearings aged and thickened. To make matters worse, resistors were installed in series with each fan to reduce the speed (and thus the noise generated by the fan) which seriously limited the starting torque and reduced the tolerance to dirt and ageing. It is no surprise that all of the later amps used passive cooling via huge heatsinks. As Krell gained market share and financial viability, the resources were available to invest in heavy heatsinks and chassis construction.